Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: SY-90-110

Brand: Suyuan

Fuel: Electric

Capacity: 500kg/h

Weight: 870kg

Certification: CE

Recycling Product: PCB

Automation: Automatic

Knife Type: Other

Feature: Environment Protection

Voltage: Country Voltage

Advantage: Easy Opperation

Function: Garbage Recycling

RAW MATERIAL: Pcb Shredder Scrap Separation Recycling

Packaging: Wooden Case

Productivity: 500-800kg/h

Transportation: Ocean

Place of Origin: Henan

Supply Ability: 30Sets/Month

Port: Qingdao,Shanghai

Payment Type: T/T

Incoterm: FOB

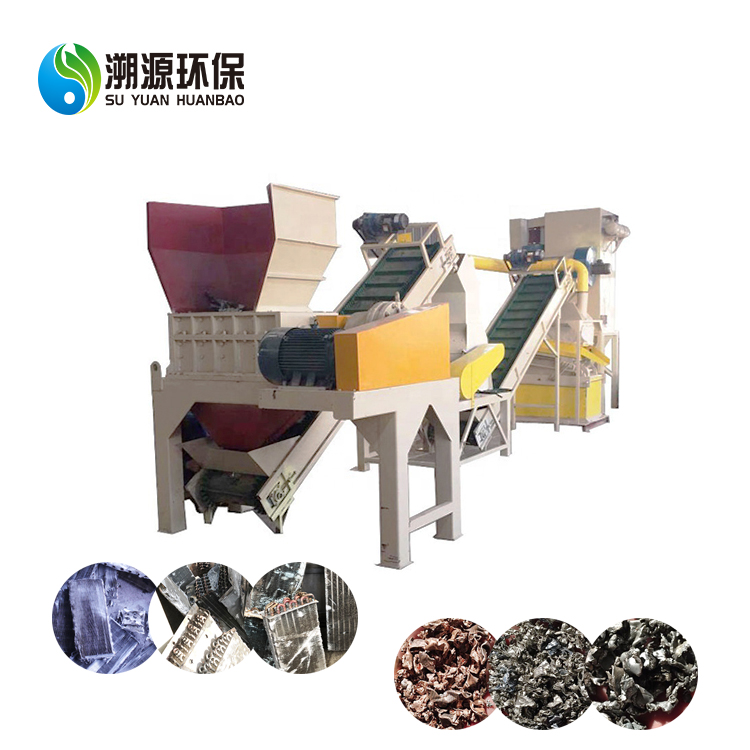

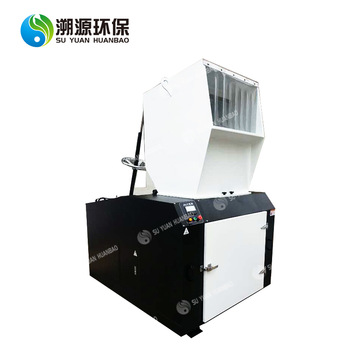

Good Quality Waste Pcb Shredder Recycling Machine

Good Quality Waste Pcb Shredder Recycling Machine is used for crushing computer motherboard, mobile phone board, miscellaneous board and other circuit boards.

Our Advantages:

1. 95% High separating rate

2. Lower noise

3. Clean without pollution

4. Easy-operated

5. Lowest price with warmed service: we promise to provide high quality product with warmed service forever.

Process:

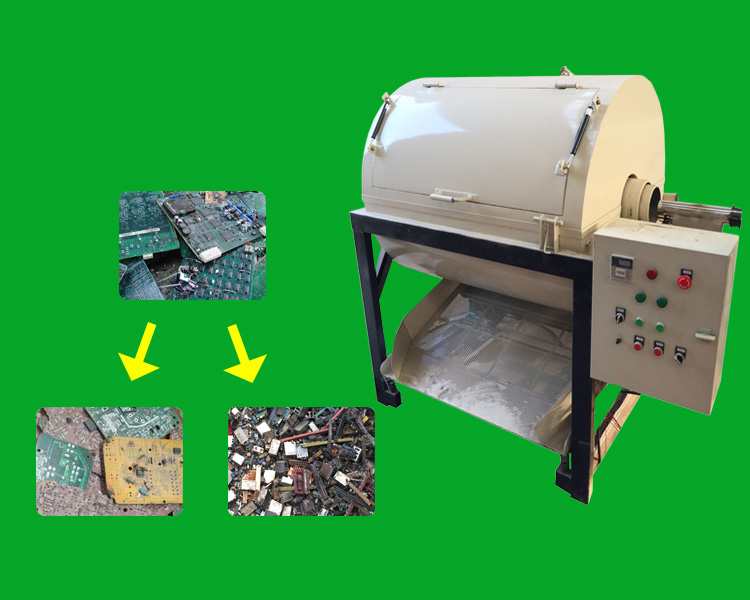

1. At first, we should put the waste circuit board with electronic components into the circuit board component disassembler to disassemble the electronic components. (The electronic component disassembler is divided into two types: electric thermocouple heating and liquefied gas flame heating, which are generated during the disassembly process. The flue gas is sprayed through a special liquid to remove odor and smoke and is adsorbed by the activated carbon adsorption tower to achieve harmless gas emission. The solder and electronic components are separately recovered through the vibration screening of the lower part of the disassembler during the entire disassembly process. After the electronic components are completely separated from the recycling, the circuit board substrate is released, and the next classification and recycling are performed.

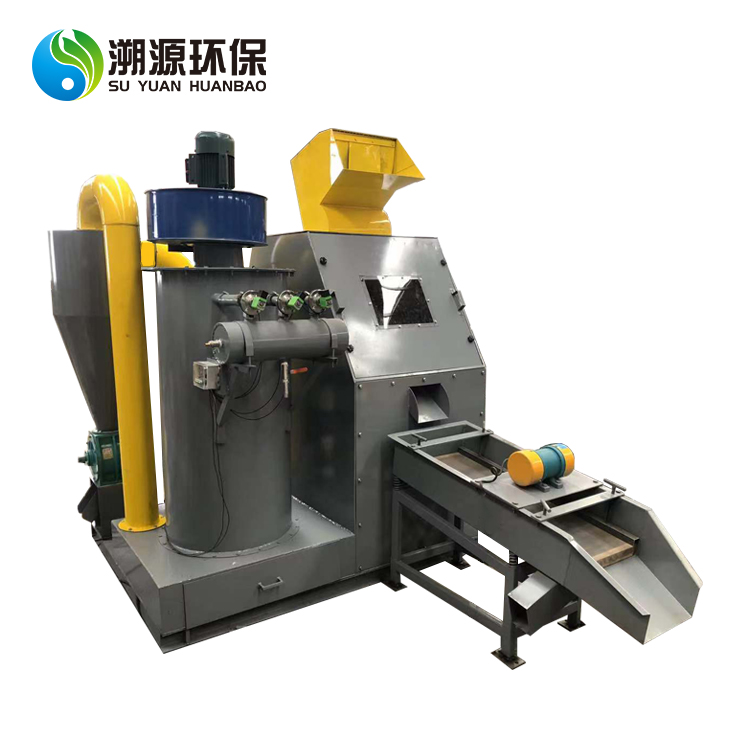

2. The electronic components are sieved according to the shape and size of the electronic components through a multi-layer linear vibrating screen. The components are roughly classified into: socket slot containing a gold-plated portion, resistor and a capacitor/diode, integrated block containing a precious metal, and so on. Considering the pins of the capacitor and the monolithic capacitor are basically tinned with a magnetic material, we can sieve out plating Tin electronic feet, aluminum and non-metal which is similar in size to the shape of the capacitor through the drum type Magnetic Separator and magnetic separation, and then collect them to for separating

them.

Model Range of temperature (℃) Speed (r/min) Power (kw) Size (mm) Weight (kg) SY-80-90 25-300 5-60 3.75 1680*980*1420 585 SY-90-110 25-300 5-60 4.75 1880*1080*1580 870

Package:

Our other products

Company Profile: China Henan Traceability Environmental Protection Equipment Co., LTD., founded in 2002,it is one of the early few domestic manufacturers of renewable resources recycling equipment.In the past 20 years, we have been focusing on the research and manufacturing of various waste resources separation, sorting and regeneration equipment. Xinxiang Traceability Environmental Protection Equipment Co. Ltd. was established in the end of 2002.For more than 18 years, we have been committed to the research and manufacture of various waste resources separation and sorting recycling equipments. Our Customer visiting Our Certificates

The company mainly produces: Pcb Recycling Machines;Copper Wire Recycling Machines;Copper Aluminum Recycling Machines;Aluminum Plastic Recycling Machines;Radiator Separator those;Plastic Recycling Machines.

The Circuit Board Dismantaling Machine, through years of market verification, has stable and reliable equipment, and the Copper Wire Recycling Machine can realize the effect of no plastic in Copper and no Copper in plastic, which is advanced in China and highly recognized in the market.

Our company always adhere to the credibility of the first, customer first principle, to achieve the combination of quality products and quality service.We will with high quality products and reputation, dedicated service and new and old customers, to jointly create a clean blue sky and efforts.

Because we are professional, we are trustworthy;Because we work hard, we do better!

The company has always adhered to the principle of “ Service First, Customer First ”. We will serve the new and old customers with high quality products and service. We will contribute to create a healthy and environmental world together !

Product Categories : Circuit Board Dismantaling Machine

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.