Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: SY-80-90

Brand: Suyuan

Fuel: Electric

Weight: 585kg

Certification: CE

Recycling Product: PCB

Automation: Automatic

Knife Type: Other

Feature: Environment Protection

Voltage: Country Voltage

Advantage: Easy Opperation

Function: Garbage Recycling

RAW MATERIAL: Pcb Board Scrap

Capacity: 450kg/h

Packaging: Wooden Case

Productivity: 300-500kg/h

Transportation: Ocean

Place of Origin: Henan

Supply Ability: 30Sets/Month

Port: Qingdao,Shanghai

Payment Type: T/T

Incoterm: FOB

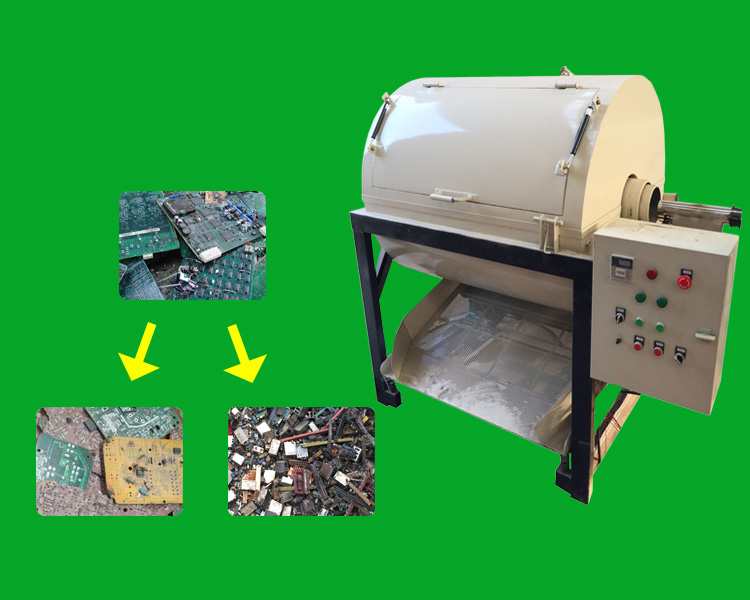

Electronic Board Dismantling Machine

Electronic Board Dismantling Machine Structure Feature:

The inner tank of the circuit board high temperature dismantling machine uses the 6mm-thick No. 45 anti-skid steel plate, and the outer wall is insulated with the insulating cotton to prevent the loss of temperature and the corresponding production technology; safe and reliable, stable performance, durable and other characteristics, use the automatic heating device of automatic temperature control, forced air supply and flameout self-ignition control, and set up the automatic memory preservation of temperature per time. It is an indispensable ideal tool in the production area of the electronic circuit board industry.

1. At first, we should put the waste circuit board with electronic components into the circuit board component disassembler to disassemble the electronic components. (The electronic component disassembler is divided into two types: electric thermocouple heating and liquefied gas flame heating, which are generated during the disassembly process. The flue gas is sprayed through a special liquid to remove odor and smoke and is adsorbed by the activated carbon adsorption tower to achieve harmless gas emission. The solder and electronic components are separately recovered through the vibration screening of the lower part of the disassembler during the entire disassembly process. After the electronic components are completely separated from the recycling, the circuit board substrate is released, and the next classification and recycling are performed.

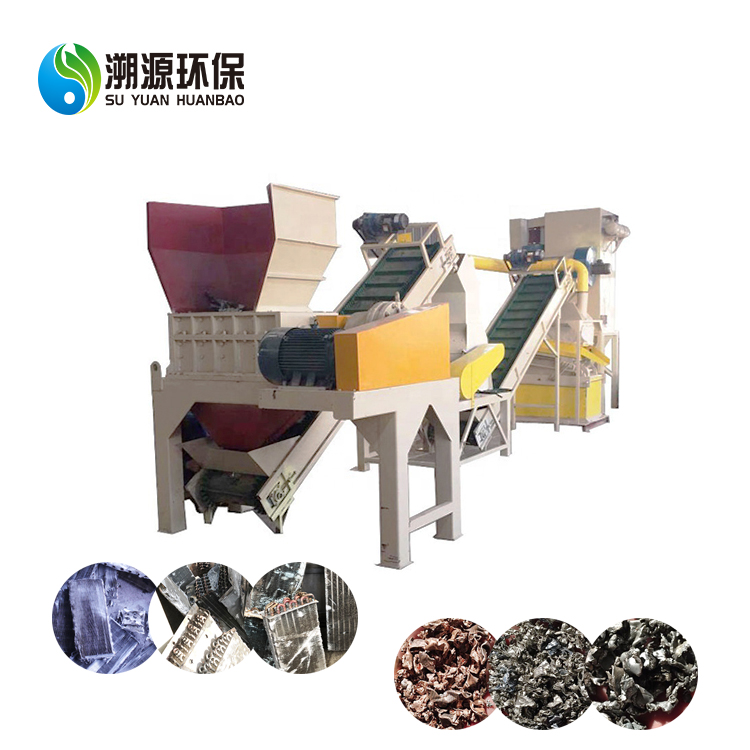

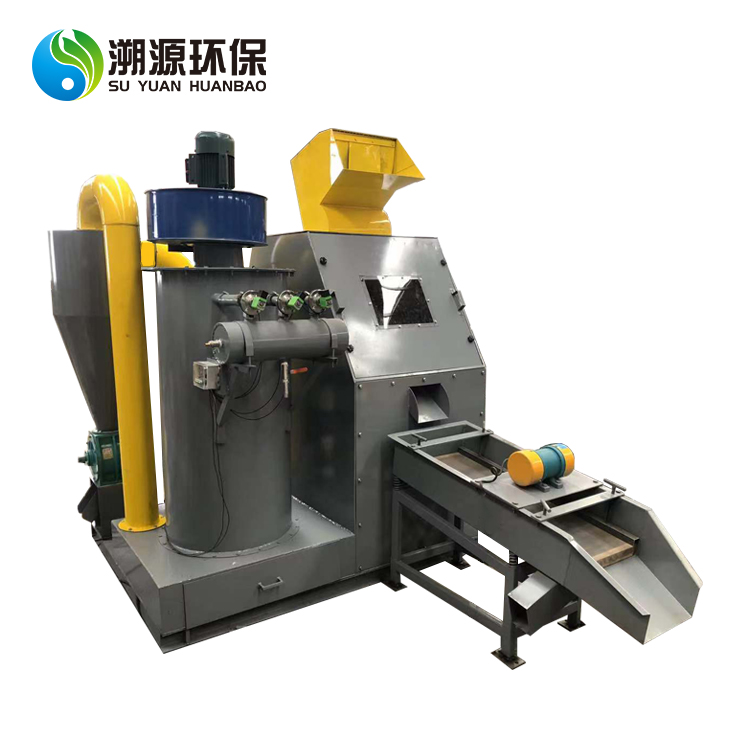

2. The electronic components are sieved according to the shape and size of the electronic components through a multi-layer linear vibrating screen. The components are roughly classified into: socket slot containing a gold-plated portion, resistor and a capacitor/diode, integrated block containing a precious metal, and so on. Considering the pins of the capacitor and the monolithic capacitor are basically tinned with a magnetic material, we can sieve out plating Tin electronic feet, aluminum and non-metal which is similar in size to the shape of the capacitor through the drum type Magnetic Separator and magnetic separation, and then collect them to for separating

them.

Model Range of temperature (℃) Speed (r/min) Power (kw) Size (mm) Weight (kg) SY-80-90 25-300 5-60 3.75 1680*980*1420 585 SY-90-110 25-300 5-60 4.75 1880*1080*1580 870

Our advantages:

1. Easy-operated: The entire assembly line uses the PLC intelligent programming automatic control and man-machine interface touch screen, so that the even feeding of the entire production line and coordinated work can be realized.

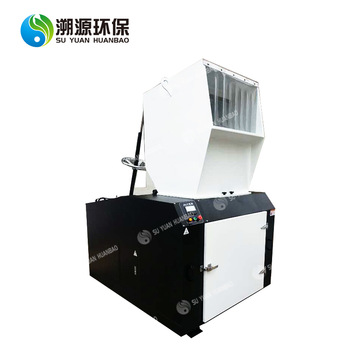

2. Lower noise: We use noise reduction treatment of the crushing equipment to reduce the noise.

3. Clean without pollution: We Use the negative pressure feeding system and pulse dust removal system to purify the working environment.

4. High separating rate: The sorting part adopts the proportion sorting combined with the static careful selection, so that the metal recovery rate can reach up to more than 99%. (Our electrostatic sorting equipment is our most important product which has won a high reputation in the world.)

5. Lowest price with warmed service: we promise to provide high quality product with warmed service forever.

Package:

Our other products

Company Profile: China Henan Traceability Environmental Protection Equipment Co., LTD., founded in 2002,it is one of the early few domestic manufacturers of renewable resources recycling equipment.In the past 20 years, we have been focusing on the research and manufacturing of various waste resources separation, sorting and regeneration equipment. Xinxiang Traceability Environmental Protection Equipment Co. Ltd. was established in the end of 2002.For more than 18 years, we have been committed to the research and manufacture of various waste resources separation and sorting recycling equipments. Our Customer visiting Our Certificates Q: Why Choose Us? 1)Eighteen year's experience,Enjoy a high reputation at home and abroad Our factory has been dedicated to recycling equipment for 18 years. Our machines have high reputation both at home and abroad (Such as the Middle East, Southeast Asia, Africa and so on more than 10 countries and regions) 2) Price advantage We are manufacturers, not dealer. Factory direct sale makes price more competitive. 3) Fast Delivery: We promise the goods can be shipped out on delivery date after confirmation of the order. Q: How to ensure the quality of the machine ? You can send your sample scrap materials to us, we will test the machine for you for free. We also warmly welcome you to visit our factory to test our machine personally. Q: Which brand of motor will you use? We use domestic motor manufatured by Chinese-famous suppliers, but you can choose Siemens or other brand motor.

The company mainly produces: Pcb Recycling Machines;Copper Wire Recycling Machines;Copper Aluminum Recycling Machines;Aluminum Plastic Recycling Machines;Radiator Separator those;Plastic Recycling Machines.

The Circuit Board Dismantaling Machine, through years of market verification, has stable and reliable equipment, and the Copper Wire Recycling Machine can realize the effect of no plastic in Copper and no Copper in plastic, which is advanced in China and highly recognized in the market.

Our company always adhere to the credibility of the first, customer first principle, to achieve the combination of quality products and quality service.We will with high quality products and reputation, dedicated service and new and old customers, to jointly create a clean blue sky and efforts.

Because we are professional, we are trustworthy;Because we work hard, we do better!

The company has always adhered to the principle of “ Service First, Customer First ”. We will serve the new and old customers with high quality products and service. We will contribute to create a healthy and environmental world together !

Product Categories : Circuit Board Dismantaling Machine

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.